By using ‘green catalysts’, Northwestern University researchers have succeeded in breaking down and rebuilding polyurethane in order to make new type of foam. This offers advantages for increasing the scope of renewables, especially given that polyurethane plastic found in everyday products from mattresses to shoes. The material is not recyclable through conventional means.

Polyurethanes are plastics with crosslinked structures (thermosets) and catalysts can be used to rearrange their bonds as they change shape. The new process uses recently identified nontoxic catalysts to allow foam to be reused and repurposed.

The “refoaming” of polyurethane occurs after heating in the presence of a zirconium-based catalyst and when a foaming agent is introduced. In trials, the recycled foam maintained its durability and structural and chemical integrity.

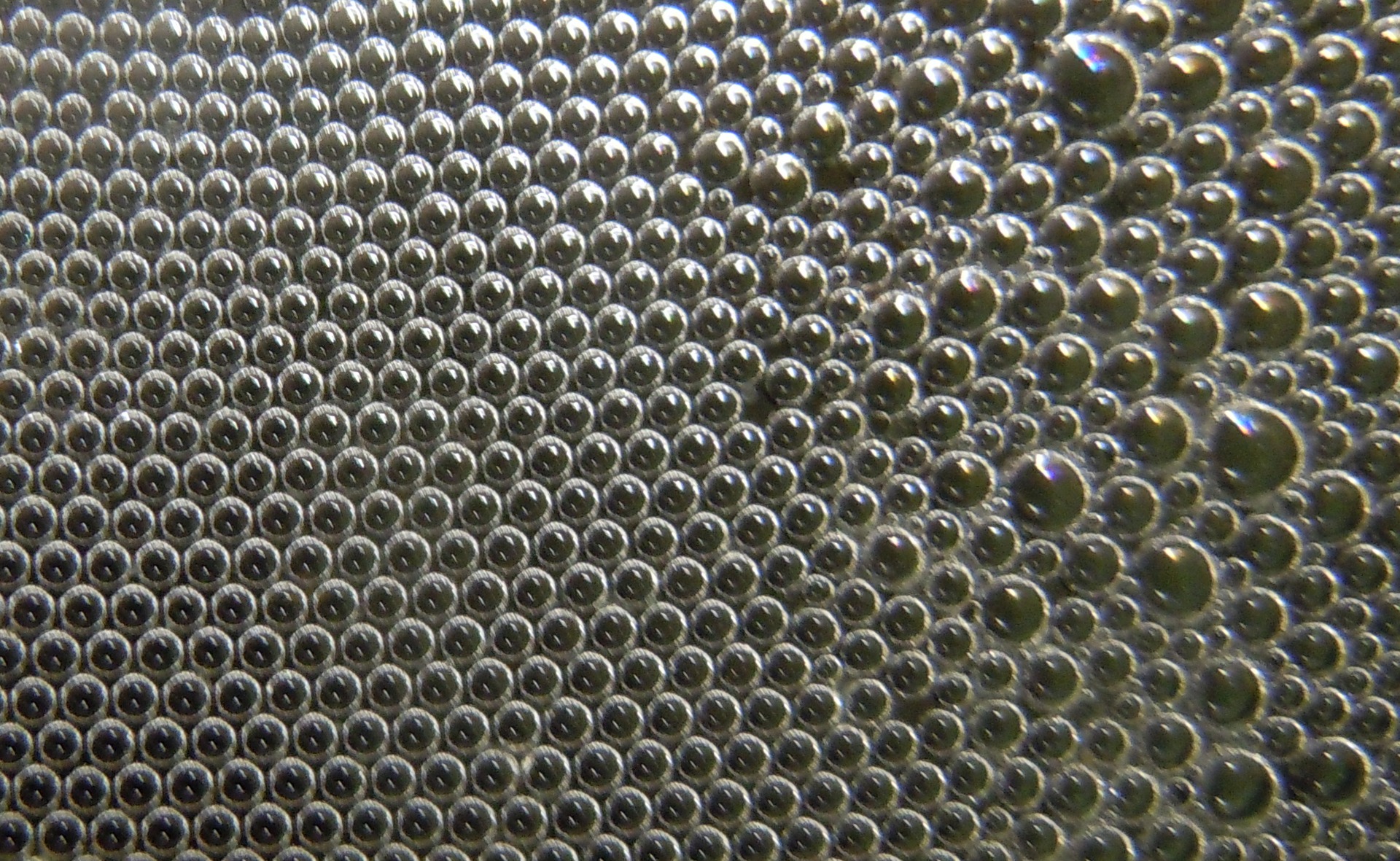

Ass the polyurethane is heated, the zirconium catalyst rearranges its bonds and allows the material to be reshaped. At the same time, a substance called a foaming agent generates new gas bubbles, which are trapped within the plastic. Through this mechanism, the old polyurethane foam, typically only used once, is transformed into a new, reshaped foam.

The catalysts proved to be capable of reprocessing a polyurethane foam for four or five cycles, maintaining the same properties in each case.

In contrast, traditional polymer plastic recycling involves melting down the plastic and then casting it for a new use. More durable plastics (like polyurethanes) do not melt down because of their crosslinked structure.

William Dichtel, the Robert L. Letsinger Professor of Chemistry at Northwestern’s Weinberg College of Arts and Sciences, assesses the research: “The types of polymers that require this catalyst approach are called thermosets, or crosslinked polymers.”

He adds: “Thermosets are important because of their superior durability and stability, but these properties come at the expense of recyclability. New methods to recycle thermosets will reduce greenhouse emissions, save energy and decrease landfill use.”

The ability to recycle one foam into another foam product was undertaken in conjunction with scientists from BASF, a major polyurethane producer.

The discovery has the potential to be applied to post-consumer polyurethane foam products or unused industrial scrap plastics. Supporting data as to the suitability of the recycled material was confirmed by dynamic mechanical thermal analysis.

The foam-to-foam extrusion process was further shown to produce controllable, continuous, and uniform foam structures, as characterized by tests for cell diameter and cell number density.

The research has been published in the journal Macromolecules. The paper is titled “Green Catalysts for Reprocessing Thermoset Polyurethanes.”